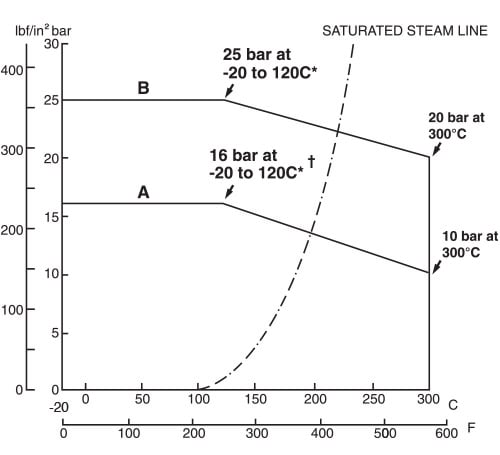

Pressure / Temperature Ratings

BS 143 & 1256:1986 states that fittings are for general purposes for the transmission of fluids within the pressure and temperature ranges specified. The ratings given are uprated from those in the 1968 edition, both for malleable cast iron and bronze fittings.

The adjacent graph shows the BS pressure temperature ratings. Crane FS malleable iron fittings are suitable for use at these new ratings with the exception of certain unions (see note Ø below), but such use is dependent on the suitability of the connecting pipe material, the threaded joint and any thread sealants used.

Due consideration should also be given to any applicable codes of practice. Pressures stated are maximum non-shock gauge.

*Hot dip zinc coated (galvanised) fittings should not be used below -10°C (14°F).

Ø Figure No. 241 unions are limited to 230°C maximum.

Figure Nos. 271, 272 and 289 unions are limited to 208°C maximum.

Dimensions given do not allow for tapping or threading tolerances.

Testing

Production testing: Meets requirements of BS EN 10242 or BS 143 and 1256 as applicable. Type testing: In addition to production testing, all pressure containing fittings are required by BS EN 10242, BS 143 & 1256 and ISO 49 to be designed to withstand specified design test pressures and to be type tested accordingly – 100 bar (1450 lbf/in2) for sizes 4 and smaller malleable iron fittings and 64 bar (928 lbf/in2) for sizes 5 and 6 malleable iron.

Tests carried out show that production fittings have safety margins well in excess of the BS requirement. Some typical burst tests on Crane FS fittings illustrate their capabilities – size 1/2 figure no. 193 bend tested to 550 bar (8000 lbf/in2) without failure; size 1 figure no. 241 flat seat union tested to 248 bar (3600 lbf/in2) without failure and size 6 figure no. 151 elbow tested to 190 bar (2750 lbf/in2) without failure.

Finish

All malleable iron fittings are given an oil finish as protection against rust while in stock or during transit and after installation prior to plant commissioning. Finished fittings are free of any polycyclic aromatic hydrocarbons.

Marking

All Crane FS fittings are marked with the logo and where size permits, the fitting size and Kitemark symbol. In addition, some castings also display a pattern identification number. This is normally located next to the band of the fitting.

This number is used during the manufacturing process as part of the rigorous quality control procedures to ensure consistent high-quality castings. The number is not of relevance to the end user of the product.

View Pipe Fittings