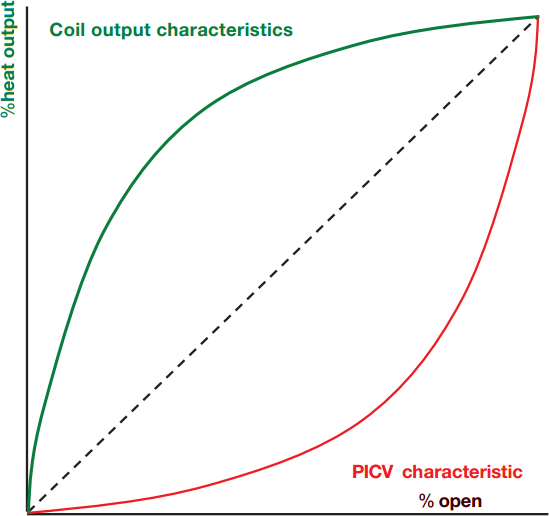

The AHU output is controlled using a control valve linked to temperature sensors in the system. As the energy output from the AHU is of a parabolic shape, an equal percentage (EQ%) control characteristic is provided by the control valve, which in turn will provide a linear response (see graph below).

The common components found within the unit include fans, heating/chilled coils, filters, attenuators and dampers. Found in applications varying from commercial offices, residential tower blocks and retail.

Recommended Solutions

Crane Fluid Systems has a number of applicable solutions available for this type of terminal. See examples below.

PICV has become the preferred solution for many designers and installers in recent years. However, the option of using the traditional DPCV method is still available and can suit certain applications.

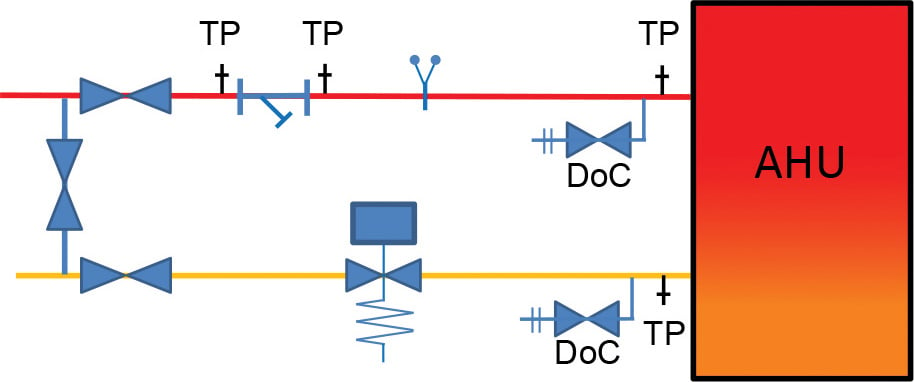

Option 1

Pressure Independent Control Valve (PICV)

PICV Stand Alone

- Easy to set up

- Straightforward commissioning

- No need for separate Commissioning Set and 2 Port Control Valve

- Size available up to DN150

Dominator w/ PICV

- Can be remotely fitted away from the terminal

- Reduced space constraints

- Extended levers available for chilled systems

- Sizes available up to DN25

AHU with PICV

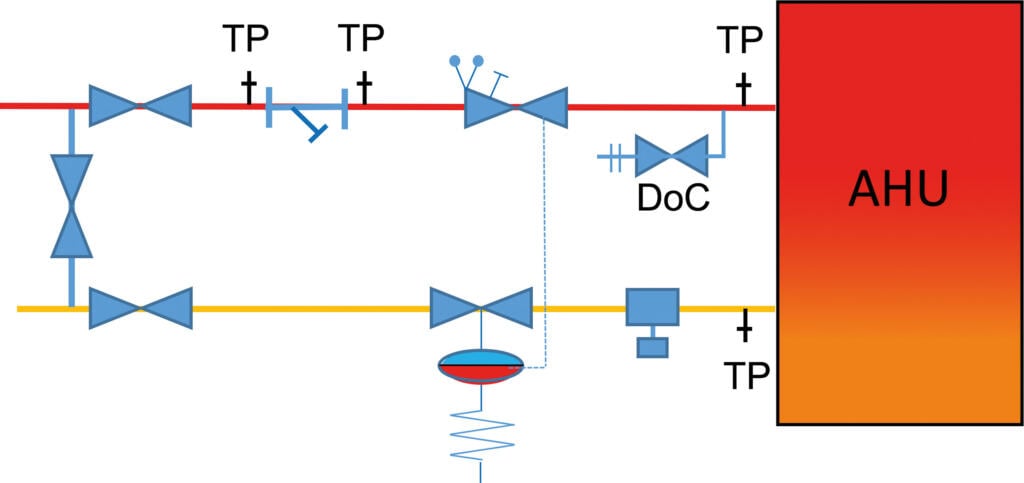

Option 2

Differential Pressure Control Valve (DPCV)

DPCV Stand Alone

- Range of controllable dPs Available

- Available with Companion Valve

- Sizes available up to DN150

Dominator w/ Comm. Set

- Available with either static Commissioning Set or Motobalance

- Available with Strainer

- Extended levers available for chilled systems

AHU with PICV