Recommended Solutions

Crane Fluid Systems has a number of applicable solutions available for this type of terminal. See examples below.

PICV has become the preferred solution for many designers and installers in recent years. However, the option of using the traditional DPCV method is still available and can suit certain applications.

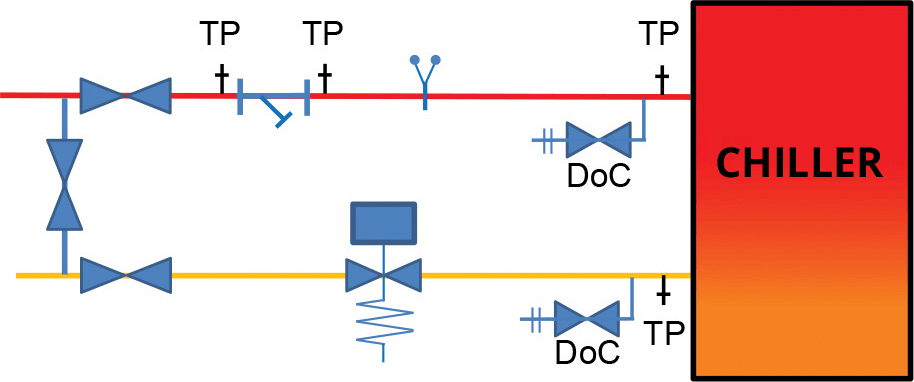

Option 1

Pressure Independent Control Valve (PICV)

PICV Stand Alone

- Easy to set up

- Straightforward commissioning

- No need for separate Commissioning Set and 2 Port Control Valve

- Size available up to DN150

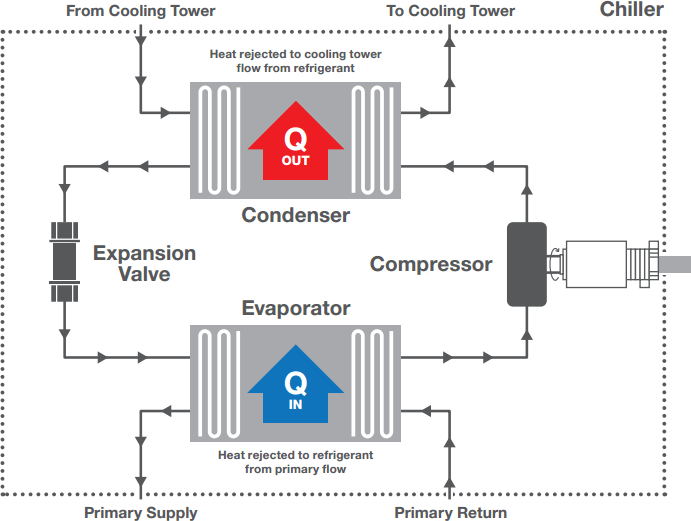

Chiller with PICV

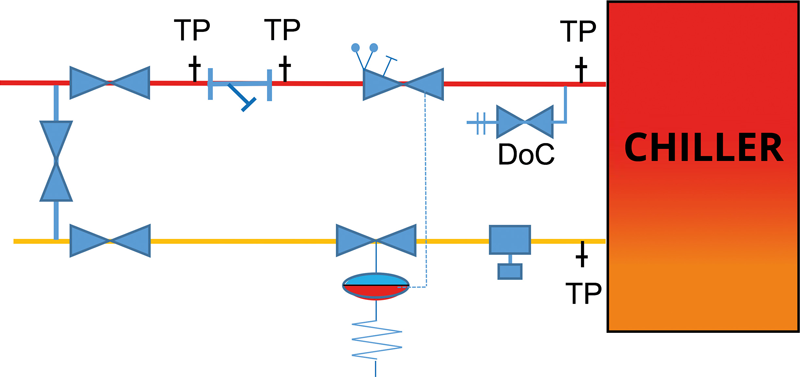

Option 2

Differential Pressure Control Valve (DPCV)

DPCV Stand Alone

- Range of controllable dPs available

- Available with Companion Valve

- Available in sizes up to DN150

- Requirement for control valves and commissioning set on individual units

Chiller with typical valve arrangement